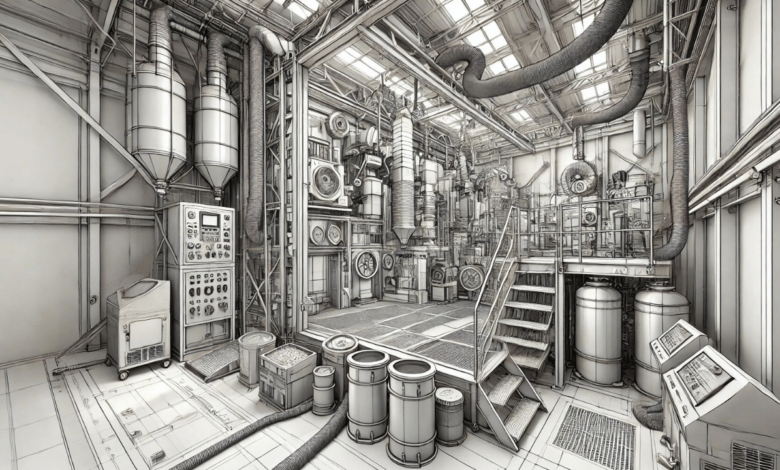

Optimizing Blast Booth Longevity Through Proper Maintenance

Modern blast booths are critical for various industrial applications, providing efficient solutions for surface preparation and finishing. To ensure these valuable assets deliver optimal performance and longevity, proper maintenance is essential. Here’s a guide to maintaining your blast booth for prolonged service life and efficiency.

Regular Inspections for Peak Performance

One of the most effective ways to extend the life of a blast booth is through regular inspections. By scheduling frequent check-ups, operators can identify and address potential issues before they become major problems. Inspections should focus on all critical components, including the ventilation system, blasting nozzles, and dust collectors. Look for signs of wear and tear, corrosion, or any unusual noises that could indicate underlying issues. Keeping a log of these inspections can help track the booth’s condition over time and predict when parts might need replacement.

Keeping Filters and Ventilation in Top Shape

The ventilation and filtration systems are the heart of any blast booth. Ensuring they are always in top condition is crucial for maintaining a safe and efficient working environment. Regularly replace or clean filters to prevent clogging and reduce dust build-up. This not only maintains air quality but also ensures that the blasting booth operates at peak efficiency. Additionally, checking the ventilation system for blockages and ensuring all fans are working correctly can prevent overheating and other operational issues that could shorten the booth’s lifespan.

Prioritizing Component Integrity and Upkeep

A blasting booth is composed of numerous components that must work in harmony. Maintaining the integrity of these parts through regular upkeep is vital. Pay special attention to the blasting nozzles and hoses, as they are subject to significant wear and tear. Replacing these parts at the first sign of deterioration can prevent more extensive damage to the system. Additionally, ensuring that the booth’s walls and doors are in good condition will help maintain a consistent and controlled environment for blasting operations.

Adopting a Proactive Approach to Cleaning

While it might seem straightforward, cleaning the blast booth is often overlooked. A proactive cleaning schedule can significantly impact the longevity of your blast booth. Regularly removing dust and debris from the booth’s interior prevents accumulation that can lead to corrosion and other issues. Make sure to clean all surfaces, including the floor and walls, to avoid uneven wear and potential damage. Using the right cleaning tools and solutions is also important to avoid harming the booth’s materials. This simple practice can go a long way in preserving the efficiency and lifespan of the booth.

Training and Best Practices for Operators

Ensuring that operators are well-trained in both using and maintaining the blast booth is another crucial factor in its longevity. Providing comprehensive training on best practices for operating and caring for the booth can prevent many common issues caused by user error. Operators should understand the importance of regular maintenance tasks and how to perform them correctly. This includes knowing how to inspect the booth, replace filters, and clean components effectively. A well-informed team can make a significant difference in maintaining a professional blast booth and ensuring its long-term functionality.

Advanced Monitoring Systems for Predictive Maintenance

Embracing technology can also play a key role in maintaining an industrial blast booth. Advanced monitoring systems can provide real-time data on the booth’s performance, highlighting any anomalies that could indicate maintenance needs. These high-tech blast booth systems can track various parameters such as pressure, airflow, and filter condition, enabling predictive maintenance. By addressing issues before they escalate, businesses can avoid costly repairs and downtime. Integrating these systems into your maintenance routine ensures that your blast booth remains in optimal condition and extends its service life.

Custom Maintenance Plans for Unique Needs

Each blast booth has unique requirements based on its size, usage, and environment. Creating a custom maintenance plan tailored to these specific needs can optimize the booth’s longevity. Consider factors like the type of materials being blasted, the frequency of use, and environmental conditions such as humidity and temperature. Custom maintenance plans ensure that all aspects of the blast booth are addressed appropriately, preventing over-maintenance of some parts and neglect of others. This targeted approach maximizes the efficiency and lifespan of both small and large blast booths.

Proper maintenance is essential for ensuring the longevity and optimal performance of your blast booth. By conducting regular inspections, maintaining filters and ventilation systems, prioritizing component integrity, adopting proactive cleaning measures, training operators, utilizing advanced monitoring systems, and developing custom maintenance plans, you can keep your blast booth in excellent condition for years to come. This approach not only enhances the efficiency and safety of your operations but also protects your investment in this essential industrial equipment.